The ultimate nozzle size guide

Have you ever tried other nozzle sizes than the standard one that came with your 3D printer? Are you wondering if it’s worth the investment to buy other nozzle sizes? This article is for you!

The standard nozzle size

The standard size for 3D printer nozzles is 0.4mm. Sometimes certain manufacturers also use 0.35mm as their standard nozzle, it doesn’t make that big of a difference.

Why is this the standard nozzle size? Because a 0.4mm nozzle simply is an allrounder! It can be used to make fairly detailed prints in a fair amount of time.

This is the fundamental truth about nozzle size: It’s always a tradeoff between print quality/resolution and speed.

Smaller nozzles

Smaller nozzles like 0.2 or even 0.15 mm nozzles are amazing for making high detailed prints. With an adapted layer height you can make objects with a SLA print like quality.

The biggest trade off with smaller nozzles is the substantially increased printing time. Your parts also might get weaker due to the decreased perimeter and infill wall widths. This also makes vasemode prints a lot trickier.

Another side effect you might experience with such small nozzle diameters is their tendency to clog. This is the case because even small contamination can cause the nozzle to clogg. If you want to learn more about clogging check out our blog post: What is nozzle clogging, how to fix it and how to prevent it.

Bigger nozzles

With bigger nozzles up to 1.2mm you lose detail, but they just spit our plastic like crazy. Huge prints just become so much quicker and stronger. Even vase mode prints get fairly strong.

But can your hotend handle it?

Because of their bigger opening, these nozzles have a greater material flow, which unless you reduce the print speed so far that it defeats the purpose of a bigger nozzle, requires your hotend to melt much more plastic in any given time period.To make this possible you could crank up the print temperature. But at some point you start degrading the print material which not only greatly reduces print quality and strength but also releases potentially harmful fumes. To circumvent this you might need a stronger hotend like the e3d volcano. Such hotends can output more thermal energy without augmenting the print temperature. The downside is that you need to convert your 3D printer, buy an other hotend which also requires you to buy special nozzles, rendering your current nozzles useless. But there is a way around that! By using a nozzle with increased thermal transfer you might be able to print faster with bigger nozzles.

We might be a little bit biased about nozzle choice but we manufacture the titan nozzle, an ultra durable nozzle out of a high thermal conductivity material with a flow optimized internal geometry. Our test show that our nozzle really increases material flow substantially. We will link to our test results once we finished compiling them. If this sparked your interest, learn more about the titan nozzle. Unfortunately it is only available with a 0.4 mm nozzle size but we work hard creating other nozzle sizes.

Nozzle size and layer height

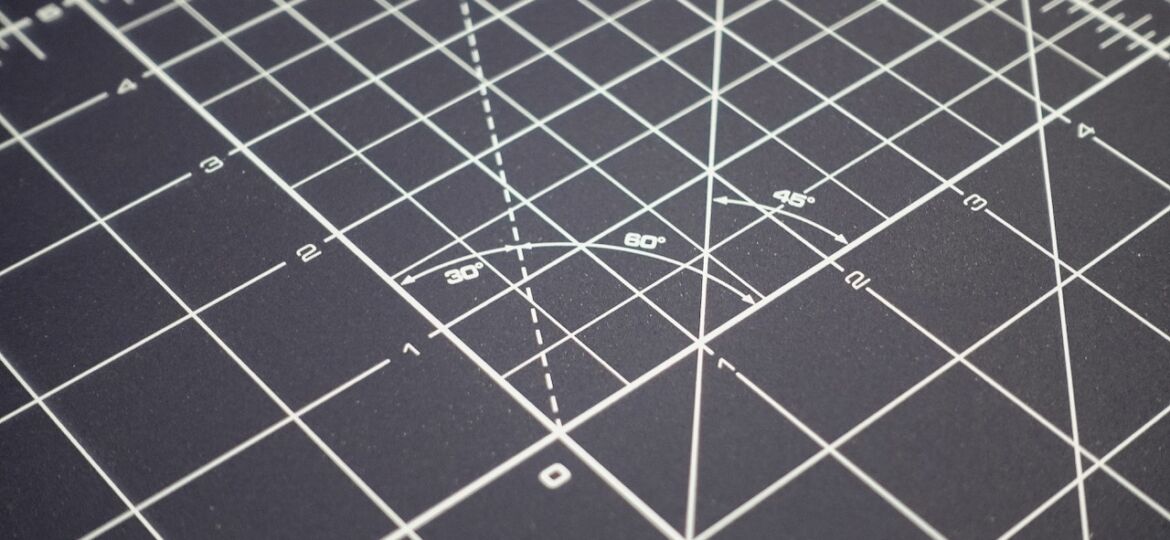

The size of your nozzle affects the layer height you should use. There are some technical limitations and, as for nozzle diameter, there is a tradeoff between print quality and speed.

As for the technical limitations, you can start with the general rule of thumb that half your nozzle diameter should be your Ideal layer height, a quarter of your diameter should be your minimum layer height and three quarters of your nozzle diameter should be your maximum layer height,but you might sacrifice reliability. But of course, like anything 3D printing related, this might need tuning.

Let’s make an example: for a 0.4mm nozzle, your ideal layer hight for the most reliable print should be 0.2mm. If you have a nicely tuned print profile, you might want to go up to 0.3mm layer height to reduce your printing time. Anything higher than that might reduce your reliability and layer adhesion. If you are looking for high resolution you can go down to 0.1m. If you go lower than that you just increase your print time with very little to no increase in print quality.

In a future article we might look deeper into layer height and into ways you can use layer heights in order to make stronger prints.

Conclusion

3D printer nozzle diameter choice basically boils down to this: everything is a tradeoff between printing time and resolution.

The 0.4mm nozzle is the allrounder. It has the ideal quality/speed relation for your everyday use.

The nozzles between 0.15 and 0.2mm are ideal for high resolution prints but come with the tradeoffs of increased print time and a higher chance of clogging

The nozzles between 0.6 and 1.2mm are ideal for big or high strength prints. They spit out material like crazy but not every hotend/nozzle combination might be able to handle it

If you are looking for a fast and reliable nozzle check out the Titan nozzle!